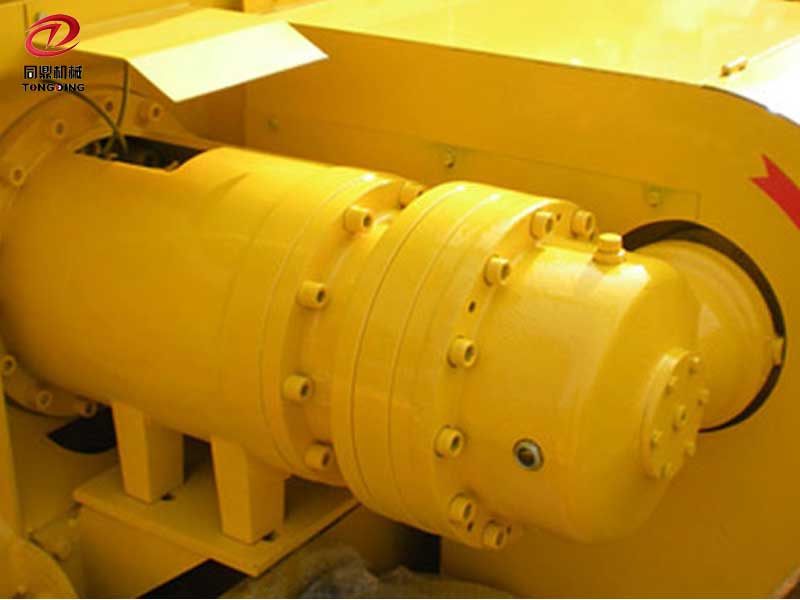

Description of TD-JS2000 Concrete Mixer:

TD-JS2000 electric concrete mixer is an important concrete mixing machine in our company. Multi-stirring piece design and unique mixing angle make the mixing faster and more uniform, which can improve the production efficiency. Water is injected into the concrete mixer, which accelerates the mixing of water and mix materials as well as thoroughly cleans it.

Features of TD-JS2000 Concrete Mixer:

1.This concrete mixer uses high-chromium and high-molybdenum scale boards and stirring pieces, with a long service time.

2. Shaft seal is applied with patented air pressure seal, which can effectively prevent the leakage of mortars.

3. Auto-lubrication system ensures the mixing system can operate continually for a long time.

4. Opening gates mechanism directed by hydraulic can adjust the opening angle of discharging door in accordance with the need, which effectively prevents overspill while discharging the finished materials into truck-mounted concrete mixers.

Technical Specification of TD-JS2000Concrete Mixer:

Model: TD-JS2000

Discharge volume: 2000L

Charging volume: 3200L

Theoretical capacity: ≥100m3

Aggregate sizes: ≤60/80mm

Working circle: 60s

Application of TD-JS2000 Concrete Mixer:

This concrete mixer is ideal for mixing stiff-consistency concrete, semi-stiff-consistency concrete, plastic concrete and other kinds of concrete in different proportional ratios.

1.This concrete mixer uses high-chromium and high-molybdenum scale boards and stirring pieces, with a long service time.

2. Shaft seal is applied with patented air pressure seal, which can effectively prevent the leakage of mortars.

3. Auto-lubrication system ensures the mixing system can operate continually for a long time.

4. Opening gates mechanism directed by hydraulic can adjust the opening angle of discharging door in accordance with the need, which effectively prevents overspill while discharging the finished materials into truck-mounted concrete mixers.

Technical Specification of TD-JS2000Concrete Mixer:

Model: TD-JS2000

Discharge volume: 2000L

Charging volume: 3200L

Theoretical capacity: ≥100m3

Aggregate sizes: ≤60/80mm

Working circle: 60s