E-mail :bright@machinery-td.com

- Home

- Products

- Video

- Case

- About

- News

- Contact

E-mail :bright@machinery-td.com

We are here to help:Easy ways to get the answers you need.

|

screw feeder |

|

|

|

|

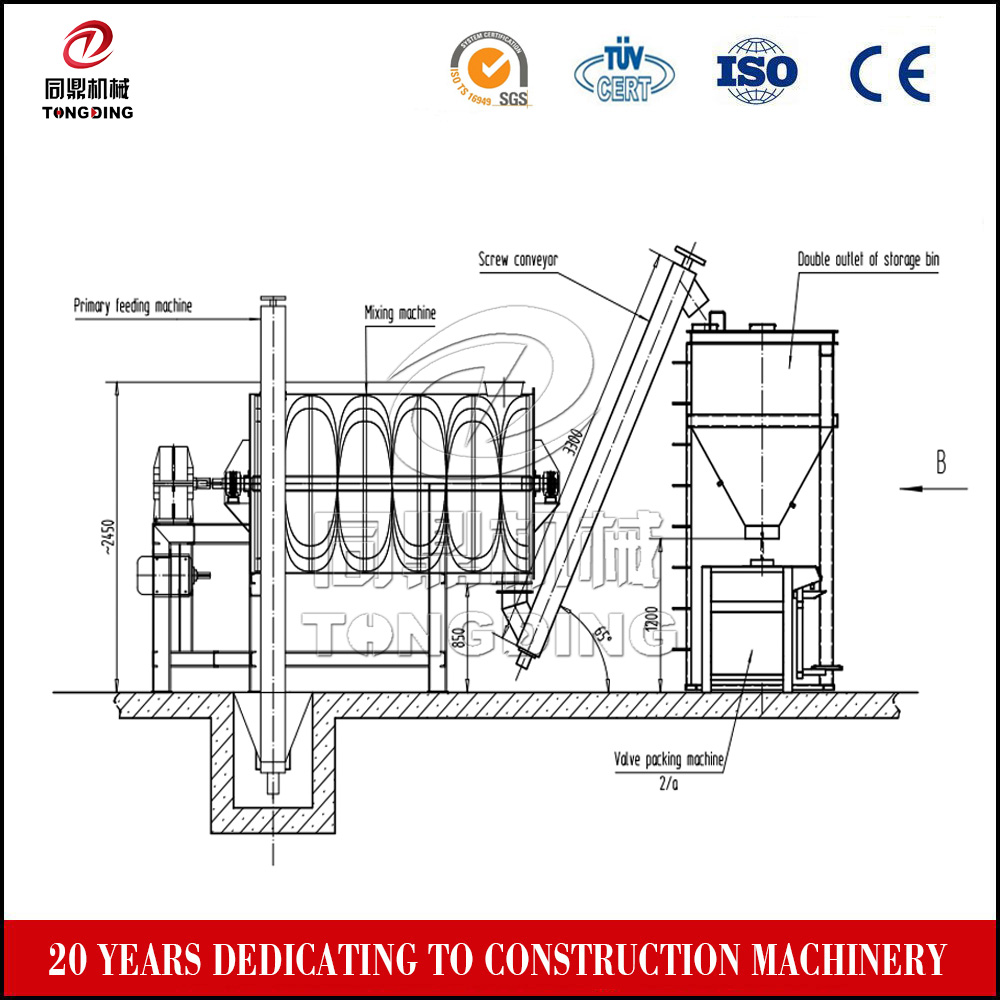

Mixer main engine |

the spiral belt wear resistant steel, long service life; backed by wheel drive settings, to prevent shaft breaking; motor reducer adopts direct type, stable quality, energy saving and environmental protection; |

|

|

|

screw feeder

|

the spiral blade adopts wear-resistant steel, patent sealing device to prevent the bearing into the dust. |

|

|

|

Finished products silo

|

come design ,export with large cablier ,rapid discharge. |

.png) |

|

|

TD-P-01

|

Professional production of valve port packing machine. All electrical components are made of high quality fittings. Automatic metering precision, high efficiency. |

|

|

|

Dust removal system |

Dust removal rate of 99%, to ensure that the working environment clean and tidy. |

|

|

1.Binding mortar:Such as tile adhesive,joint mixture,Special adhesive mortar for thermal insulation composite system,etc.

2.Plastering mortar:Such as exterior wall coating mortar,putty,color decoration mortar,thermal insulation mortar,etc4.Floor mortar:Such as ordinary floor mortar,Self-leveling mortar,etc.

5.Special mortar:Such as repair mortar,waterproof mortar,hardening powder,etc.

1.Widely applicable range: this device can meet the different performance requirements of dry mortar, such as plastering mortar, masonry mortar, insulation mortar, decoration mortar and so on all kinds of dry powder mortar.

2.Cost-effective: used for dry mortar and decoration mortar production projects, with less investment, high efficiency, and avoid the idle and waste of resources which caused by excessive investment in equipment.

3.Simple and convenient operation: the advantages of this type dry mortar mixer is a small coverage, low energy consumption, easy operation,installed directly, per hour 6-20 tons, 1-3 workers operation.

inquiry* Describe Your Buying Requirements in Detail