E-mail :bright@machinery-td.com

- Home

- Products

- Video

- Case

- About

- News

- Contact

E-mail :bright@machinery-td.com

We are here to help:Easy ways to get the answers you need.

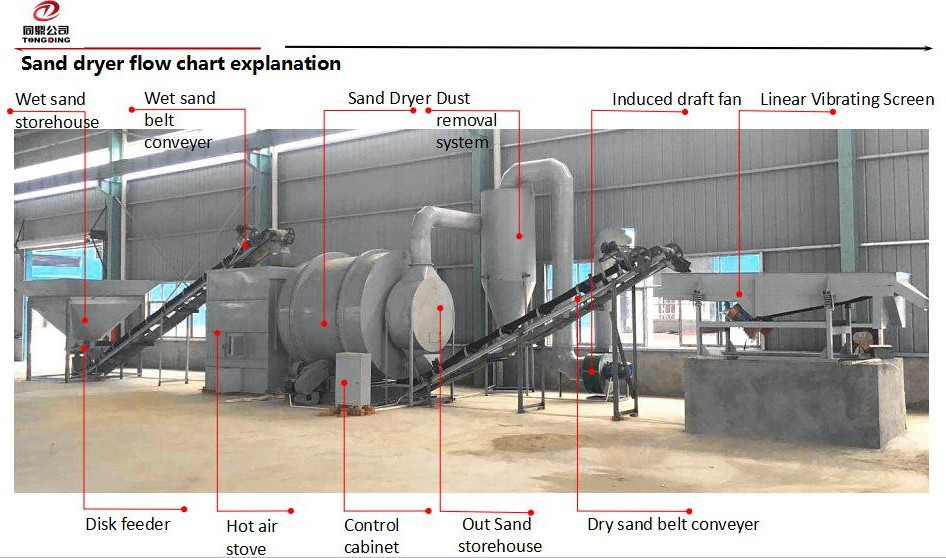

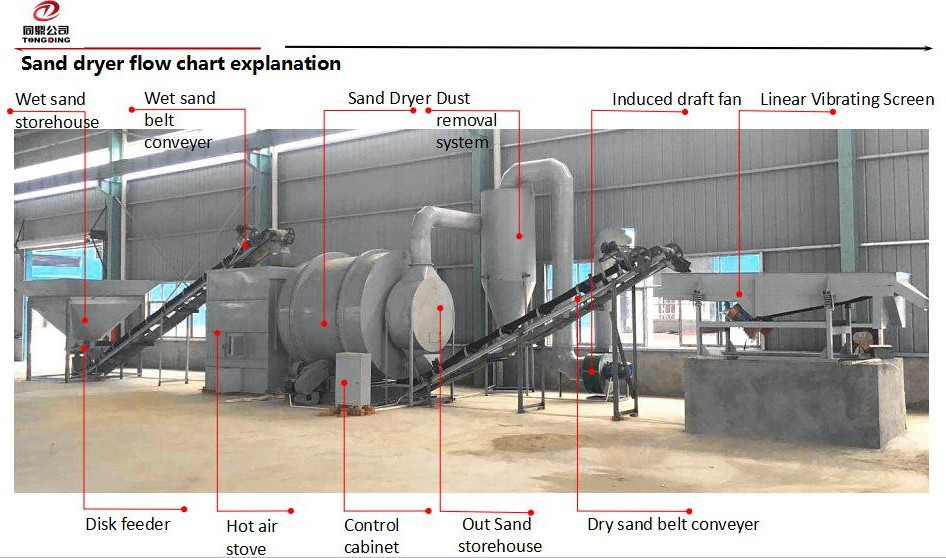

Wet sand convey:Wet sand enter into wet sand hopper,through belt feeder and wet sand belt,convey wet sand to sand dryer.

Sand drying:After the wet sand enters the dryer, it rolls inside the dryer and comes in contact with hot air to fully dry it and turn it into dry sand.

Dust removal:When dry sand comes out of the dryer, a lot of dust will be formed, and the dust collector is a device that separates the dust from the flue gas.

Dry sand screening:Customize different screens according to customer requirements to screen the sand types required by customers

Widely used in building materials , metallurgy , chemical industry, cement industry bake dry limestone slag , fly ash , coal dust, slag, clay and other materials.

1. The dryer is of strong overload capacity resistance, large process load, low fuel consumption, and low cost.

2. It adopts direct flow drying method. The gas fume and the material go to the dryer from the same side. By using the hyper thermal gas fume, the evaporation strength is very high. With the low outlet temperature, the heat efficiency is very high.

3. The operating parameter can be changed according to different materials. So that the material can form a stable fabric curtain and achieve fully heat exchange.

4. The new type feeding and discharging device solve the problem of feeding jam, discontinuous and uneven feeding, and returning charge which lighten the load of dedusting system.

5. The new inner structure strengthens the cleaning and heat conduction of the dispersed material, and eliminates the bonding in the inner drum wall. The adaptability to the material moisture and stickiness is stronger.

| Specific-ations(m) | Capacity(t/h) | Main motor | Main gear box | Weight(t) | ||

| Power(kw) | Model | Model | Speed reduction ratio | |||

| ø1.2*10 | 2.5 | 7.5 | Y160M-R3 | ZL50-16-I | ----- | 13.5 |

| ø1.5*12 | 3.3-4.9 | 10 | Y160L-6-B3 | JZQ500-III-2F | ----- | 18.9 |

| ø1.5*15 | 4-6 | 18.5 | Y200L1-6 | JZQ500-III-2F | ----- | 21 |

| ø1.8*12 | 4-6 | 18.5 | Y160L-6 | ZQ50-16II-2 | 16.46 | 22.83 |

| ø2.2*12 | 7-12 | 18.5 | Y200L7-6 | JZQ650-III | 31.5 | 37.6 |

| ø2.2*14 | 7-12 | 22 | Y200L7-6 | JZQ650-III | 31.5 | 40 |

| ø2.2*16 | 12 | 30 | Y225M-6 | JZQ750-III | 31.5 | 45 |

| ø2.4*14 | 12 | 30 | Y250M-6 | JZQ750-III | 31.5 | 51 |

| ø2.4*18 | 10-13 | 37 | Y250M-6 | ZL85-13-I | 27.16 | 54 |

| ø2.4*20 | 10-14 | 37 | Y250N-6 | ZL85-13-I | 27.16 | 54.14 |

| ø3*20 | 25 | 55 | Y250M-4 | ZL100-16-I | 41.52 | 78 |

| ø3*25 | 32-36 | 75 | YR280M-4 | ZL100-16-I | 41.52 | 104.9 |

inquiry* Describe Your Buying Requirements in Detail